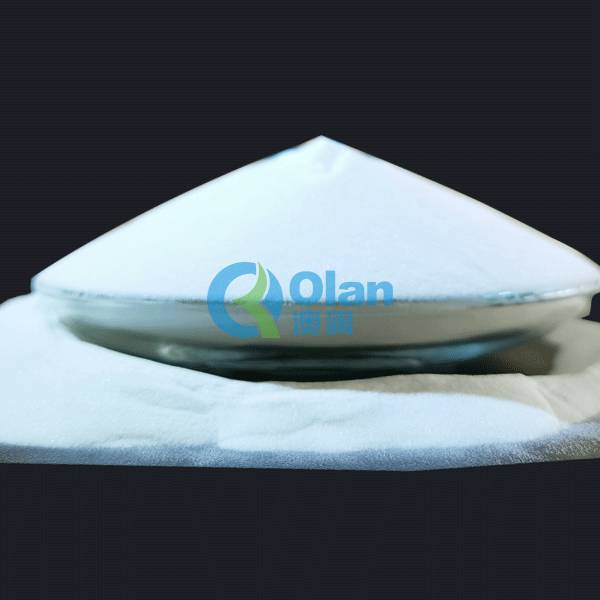

Sandblast Glass Kpụrụkpụrụ Ọlamma 280 #

Ọrụ Ọrụ

Mgbu ọkụ na Glass Beads n'okpuru nrụgide ga-ejigide ngwaahịa ndị ahụ na-enweghị mgbanwe akụkụ, na-enweghị mmetọ yana na-enweghị nrụbiga oke. Ọ na-arụpụta a na-agbanwe agbanwe Metallurgical dị ọcha elu imecha. Otutu ọgbụgba ọkụ Materials dị ka Aluminium oxide, ájá, Steel gbaa ga-ma na-ahapụ a Chemical Film na gbawara n'elu ma ọ bụ nwere ọnwụ ihe. Igwe bekee na-adịkarị ntakịrị ma gbaa ọkụ karịa usoro mgbasa ozi ndị ọzọ ma enwere ike iji ya na-acha ọkụ nke eriri na akụkụ siri ike ebe a chọrọ oke ike. Mgbasa ọgbụgba na Glass Beads na-akwadebe ala igwe maka ụdị mkpuchi ọ bụla na ya dị ka eserese, ịchacha enameling ma ọ bụ iko iko. Uru ndị ọzọ nke ọgbụgba ọkụ iko na-agụnye na ị nwere ike iji ha maka oge ole na ole tupu ha ehichaa elu. Ọ bụ ihe a na-ahụkarị maka mgbasa ozi bekee na-emechi 4 - 6 cycles tupu ọ dị mkpa ka edochi ya. N'ikpeazụ, a pụrụ iji chaplet mee ihe na mmiri ma ọ bụ na-arụ ọrụ n'ime ụlọ. Nke a na-eme ka ọ vasatail na nwere ike inyere na-enye a gbawara ihicha media na-eme gị gbawara kabinet-akwụ ụgwọ ala.

Nkọwapụta Ngwaahịa

Main ngwaahịa nkọwapụta maka sandblasting dị ka ndị na-esonụ table:

| Mbanụ. | Dayameta (um) | Ekekọtara ọnụ sieve size |

| 1 | 850-425 | 20-40 |

| 2 | 425-250 | 40-60 |

| 3 | 250-150 | 60-100 |

| 4 | 150-105 | 100-140 |

| 5 | 105-75 | 140-200 |

| 6 | 75-45 | 200-325 |

Nwere ike ịhọrọ oke iko iko dị iche n’etiti 45um-850um dịka ọrụ dị iche iche.

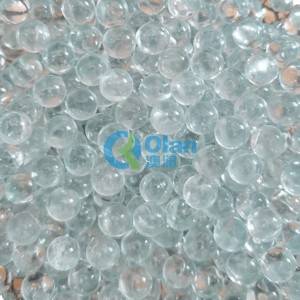

High Ike Glass chaplet (maka ọgbụgba ọkụ)

Na abịakọrọ ikuku dị ka anwansị ike, ngwaahịa a na-mere site sprinkling chaplet n'okpuru nnukwu ọsọ na mgbali n'elu workpiece maka peening na polishing.

Ebumnuche ndị ọzọ nke ngwaahịa ndị a:

1. Clear iche iche Ebu nke mmetụta ibe ya bụrụ, ibe ya bụrụ, iko, roba na plastic, metal nkedo na extrusion.

2. Kwụsị nchegbu mgbatị, mụbaa ndụ ike ọgwụgwụ ma bulie nrụgide nrụrụ corrosion. Dịka ọmụmaatụ, turbo engine ụgbọ elu, vane, shaft, undercarriage, mmiri dị iche iche na gia, wdg.

3. Hichaa ma wepu slitter onu na burr na circuit efere na plastic-kaa akara geminate transistors tupu stannum soldering

4. Wepu ị ga na piston na cylinder ma nye elu na-enwu gbaa na ọkara-enweghị ezi maka ọgwụ na ahụ ike na akụkụ ụgbọala.

5. Electromotor doro anya na akụkụ ndị dị ka akaghị, brush eletrik na rotor nke n'oge nrụzi dị arọ

6. Hichaa ma wepu burr nke metal tube na kpomkwem-gbazee na-abụghị ferrous metal tube. A ga-eji maka peening aggrandizement na polishing nke akwa igwe akụkụ.

High Ike Glass chaplet maka ọgbụgba ọkụ

| .Dị | Ntupu | Mkpụrụ ọka μ m |

| 30 # 1 | 20-40 | 850-425 |

| 40 # 40 | 30-40 | Ogbe 600-425 |

| 60 # 60 | 40-60 | 425-300 |

| 80 # # | 60-100 | 300-150 |

| 100 # # | 70-140 | 212-106 |

| 120 # # | 100-140 | 150-106 |

| 150 # | 100-200 | 150-75 |

| 180 # # | 140-200 | 106-75 |

| 220 # | 140-270 | 106-53 |

| 280 # # | 200-325 | 75-45 |

Akwụkwọ

Mbukota

Dị ka ndị ahịa chọrọ.